What is Polyimide Fiber? A Comprehensive Guide

2025-02-27 13:53

What is Polyimide Fiber?

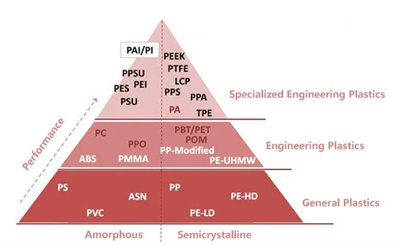

Polyimide is a class of polymers known for their robust molecular structure, which grants them resistance to heat, chemicals, and mechanical stress. Polyimide fiber, derived from this polymer, is engineered to maintain integrity in temperatures exceeding 300°C, making it ideal for high temperature filter systems and industrial applications. Unlike conventional polyamide textiles, polyimide fibers excel in harsh conditions due to their hydrolysis resistance and low thermal degradation.

Key Properties of Polyimide Fiber

1. Flame Retardant Material

Polyimide fiber is inherently flame retardant, meaning it self-extinguishes upon exposure to fire. This property makes it invaluable for manufacturing flame retardant filaments used in protective clothing, aerospace components, and electrical insulation.

2. Polyimide Thermal Conductivity

Despite its heat resistance, polyimide fiber exhibits low thermal conductivity, ensuring effective insulation in high-temperature environments. This balance makes it suitable for electronics and automotive industries.

3. Hydrolysis Resistance

Unlike many polymers, polyimide fiber resists degradation from moisture and steam, a trait known as hydrolysis resistance. This quality ensures longevity in humid or wet industrial settings.

4. High Temperature Filtration

Polyimide fibers are widely used in high temperature filtration systems, such as industrial baghouses, where they trap particulate matter without degrading under extreme heat.

Applications of Polyimide Fiber

● High Temperature Filter Media

Industries like cement production and metallurgy rely on polyimide material for filter bags that withstand prolonged exposure to heat and corrosive gases.

● Flame Retardant Textiles

From firefighter gear to military uniforms, flame retardant fibers like polyimide provide lightweight yet durable protection against flames and thermal hazards.

● Electronics and Aerospace

The polyimide thermal conductivity profile makes it ideal for insulating wires, circuit boards, and spacecraft components.

● Chemical Processing

Thanks to hydrolysis resistance, polyimide fibers are used in seals, gaskets, and hoses exposed to aggressive chemicals.

Polyimide vs. Polyamide Textiles

While polyamide textiles (e.g., nylon) are popular for their flexibility and affordability, they lack the extreme heat and chemical resistance of polyimide fiber. For applications demanding flame retardant materials or high temperature filtration, polyimide outperforms traditional synthetics.

Why Choose Polyimide Fiber?

● Unmatched thermal stability (up to 400°C)

● Superior flame retardant filament capabilities

● Resistance to chemicals, abrasion, and UV radiation

● Long service life in demanding environments

Conclusion

Polyimide fiber is a game-changer for industries requiring materials that thrive under extreme conditions. Its flame retardant, heat-resistant, and hydrolysis resistance properties position it as a superior alternative to conventional polyamide textiles and other polymers. Whether for high temperature filter systems or advanced protective gear, polyimide fiber delivers reliability and performance.

Optimize your operations with polyimide solutions—contact us to learn how our flame retardant fibers and materials can meet your needs.