Analysis of Carbon Fiber Prepreg Preparation Technology and Product Applications

2025-01-23 15:41

Carbon fiber prepreg is an important intermediate product of composite materials, which is composed of matrix resins (such as epoxy, phenolic, bismaleimide, etc.) and reinforced fiber (such as carbon fiber, glass fiber, aramid fiber, basalt fiber, etc.).

Material Composition and Advantages of Carbon Fiber Prepreg

Carbon fiber prepreg is mainly composed of reinforcing materials (carbon fiber yarn, epoxy resin) and release paper, and is processed through processes such as coating, hot pressing, cooling, laminating, and winding. Its advantages include:

1. Good mechanical properties: The strength of carbon fiber can reach 6 to 12 times that of steel, while the density is less than 1/4 of steel.

2. Few product defects: Prepreg can reduce defects in the production process.

3. Accurate control of fiber volume content: Ensure the consistency of product performance.

4. Consistent performance and processing characteristics: Suitable for large-scale production.

5. Optimal performance/weight ratio: Combines high strength and lightweight characteristics.

Classification of Carbon Fiber Prepreg

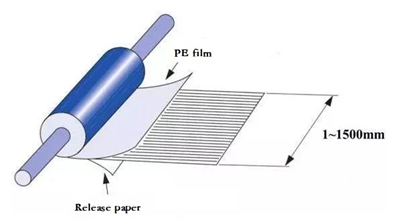

1. Unidirectional prepreg (UD): The fibers are arranged in a single direction and are suitable for applications that require high strength and high rigidity.

■ 12K: 50~400g/m²

■ 16K: 75~560g/m²

■ 24K: 75~400g/m²

■ 48K or 50K: 150~600g/m²

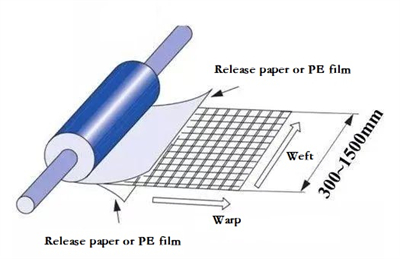

2. Fabric prepreg: Includes plain weave, twill, and non-crimp fabric (multiaxial fabric) types.

■ Plain weave: Poor paving performance, high fiber bending rate.

■ Twill: Medium paving performance, medium fiber bending rate.

■ Non-crimp fabric: Medium paving performance, no fiber bending.

Preparation Process of Carbon Fiber Prepreg

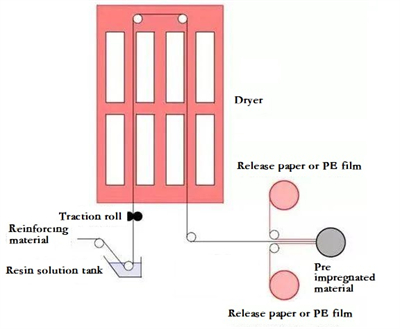

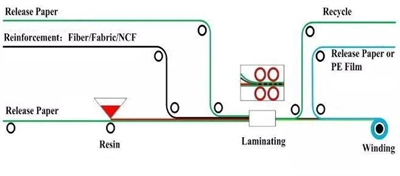

1. Solvent-based process: Suitable for the preparation of fabric prepreg.

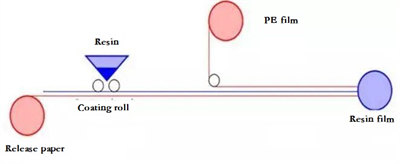

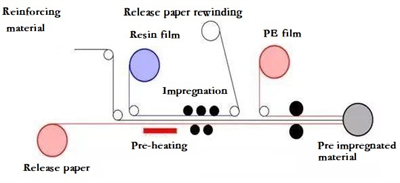

2. Two-step thermosetting prepreg process: Includes resin film preparation and impregnation process, which is the mainstream process.

■ Resin film preparation: PE film resin coating roller resin film release paper

■ Impregnation: Hot melt method

3. One-step process: High production efficiency, convenient and reliable operation, but large material loss, high energy consumption.

Application of Carbon Fiber Prepreg

1. Vacuum bag-high temperature curing process: Applied to aerospace, wind power, shipbuilding, automotive, rail transit interior parts, etc.

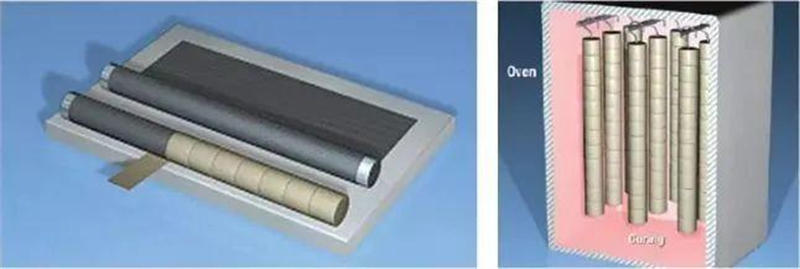

2. Autoclave process: Used for high-quality composite products and structural components.

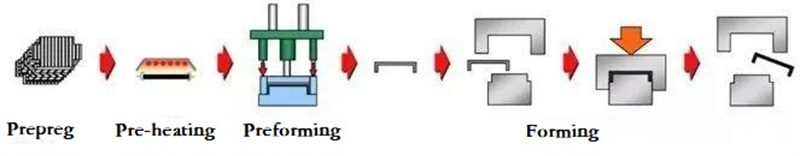

3. Prepreg molding process (PCM process): Suitable for the production of complex-shaped products.

4. Prepreg tape winding process/preimpregnated yarn editing process: Applied to fishing rods, golf clubs, ski poles, pipeline pressure vessels, etc.

Process Selection

In the selection of manufacturing processes, it is necessary to consider the product category and the customer's requirements for quality and cost. Specifically:

1. Vacuum bag-high temperature curing process: Suitable for products that require lightweight, high strength, and high performance, such as aerospace and wind power fields.

2. Autoclave process: Suitable for the production of high-quality composite products and structural components, which can provide better dimensional accuracy and surface quality.

3. Prepreg molding process (PCM process): Suitable for large-scale production of complex-shaped products, with high production efficiency and low cost.

4. Prepreg tape winding process/preimpregnated yarn editing process: Suitable for the production of long strip or tubular products, such as fishing rods, golf clubs, and pipeline pressure vessels.

Through the above introduction, we can see that carbon fiber prepreg has a wide range of applications in the field of composite materials. Its excellent performance and diversified preparation processes make it one of the indispensable materials in modern industry.