Polyimide (PI) - The Pinnacle of Polymer Materials

2025-01-07 13:09

Overview of Polyimide (PI)

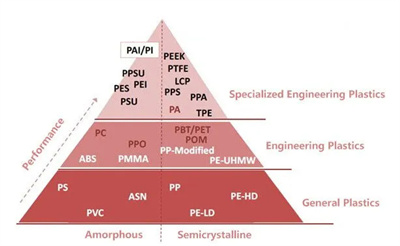

● Definition: Polyimide (PI) refers to a class of high-molecular-weight polymers containing imide groups in their main chains. The high-performance PI family primarily features aromatic and heterocyclic structural units in their backbones.

● Properties: PI possesses the highest flame retardancy rating (UL-94), excellent electrical insulation, mechanical strength, chemical stability, aging resistance, radiation resistance, and low dielectric loss. These properties remain stable over a wide temperature range (-269°C to 400°C), earning PI the title of "one of the most promising engineering plastics of the 21st century" and the nickname "the problem solver."

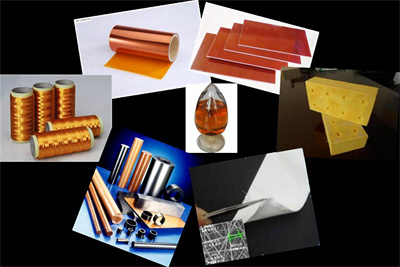

Applications of Polyimide

● PI's superior performance and processing characteristics enable it to be made into various products for diverse applications. Among polymers, PI stands out as the only one with a wide range of applications and outstanding performance in each field.

Key Polyimide Products and Their Applications

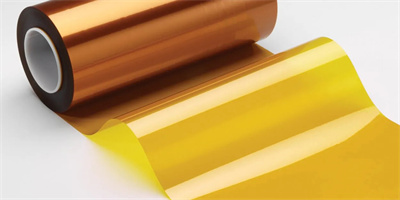

1. Polyimide Film (PI Film)

● Introduction: PI film was one of the earliest PI products to enter commercial circulation and remains the most widely used. It is the world's best-performing insulating film, applied in aerospace, microelectronics, nuclear energy, electrical insulation, LCD technology, and membrane separation.

● Nickname: Due to its high price, technical barriers, and exceptional performance, PI film is also known as "gold film."

● Market Prospects: The global PI film market was valued at $15.2 billion in 2017 and is projected to reach $24.5 billion by 2022.

2. Polyimide Fiber (PI Fiber)

● Properties: PI fiber is one of the highest temperature-resistant synthetic fibers, capable of use at 250-350°C. It outperforms aramid and polyphenylene sulfide fibers in light resistance, water absorption, and heat resistance. PI fiber has double the strength of aramid fiber.

● Applications: Includes aerospace (lightweight cable sheaths, high-temperature-resistant specialty braided cables, large-diameter deployable satellite antenna tension cables), environmental protection (high-temperature industrial dust filtration materials), and fire protection (high-temperature flame-retardant specialty protective clothing).

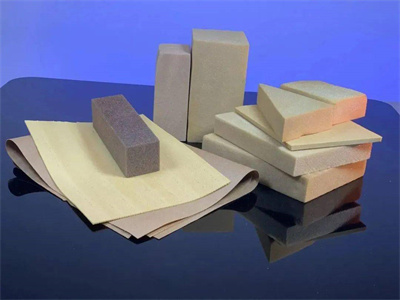

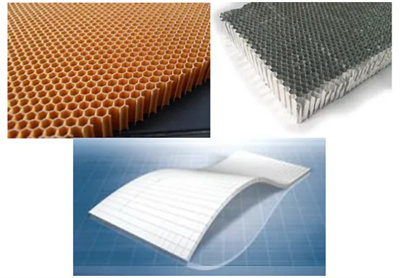

3. PI/PMI Foam

● Classification: PI foam has imide groups in the main chain and operates above 300°C. PMI foam features imide rings as side groups.

● Applications: PI foam is used for thermal insulation and noise reduction in naval ships. PMI foam, with high specific strength, modulus, closed-cell rate, and heat resistance, is ideal for structural foam cores in wind turbine blades, helicopter blades, aerospace, and more.

4. PI-based Composites

● Properties: PI resin-based composites excel in high heat resistance, mechanical properties, dielectric properties, and solvent resistance, making them the highest temperature-resistant resin-based composites.

● Applications: Widely used in aerospace, especially aircraft engines, and other fields.

5. Photosensitive Polyimide (PSPI)

● Properties: PSPI combines imide rings and photosensitive groups, offering excellent thermal stability, mechanical properties, chemistry, and photosensitivity.

● Applications: Used in photoresist and electronic packaging. PSPI photoresist simplifies processing steps compared to traditional photoresist. As an advanced electronic packaging resin, PSPI is applied in buffer coatings, passivation layers, alpha-ray shielding, interlayer insulation, and chip packaging.

Conclusion

● Challenges and Opportunities: The PI industry has high technical barriers. Foreign countries strictly embargo PI materials, technologies, and products related to aerospace, military, and high-end electronics. Domestic enterprises are catching up but still lag behind international standards. However, with ongoing research and development, there is significant potential for domestic PI products to meet and exceed international standards, ensuring self-sufficiency and technological independence in this critical field.