Wet Nonwoven Fabric Technology: Advantages, Applications, and Environmental Benefits

2025-01-02 12:00

The wet nonwoven fabric technology is a new technique that utilizes papermaking equipment and technology to produce nonwoven fabric products or paper-cloth composite materials. It has been widely adopted in countries such as China, Japan, and the United States, forming large-scale industrial advantages. This technology breaks through traditional textile principles by avoiding labor-intensive and inefficient processes like carding, spinning, and weaving.

Instead, it leverages papermaking's wet web formation technology, allowing fibers to be formed into a net and shaped in one go on the paper machine, thus greatly reducing labor intensity and improving productivity. The technology does not involve repeated processing of fiber raw materials; it directly produces fiber products from short fibers, which can reduce energy consumption, save manpower and resources, and lower manufacturing costs.

Key Points:

1. Facilitates small-scale paper mills transition and environmental pollution management.

● Utilizes existing papermaking equipment without major technical modifications for producing nonwoven fabric products.

● The entire production process generates no dust or harmful gases, and no waste liquid is discharged, making it practical for small paper mills to manage environmental pollution and develop new products.

2. Conserves water resources.

● Uses less water in production, which circulates internally within the system and is not discharged, thereby protecting water resources.

● Helps alleviate excessive water usage by small paper mills, contributing to water conservation.

3. Wide range of raw material sources.

● Due to its web-forming technical characteristics, it has strong adaptability to different raw materials and allows for a wide selection of fiber types based on product requirements.

● Available materials include plant fibers, polyester, polypropylene, vinylon, viscose fibers, and glass fibers, which can be used individually or mixed in proportions to impart special functions to the product. There are many domestic manufacturers providing these materials.

4. Diverse product varieties and wide application fields.

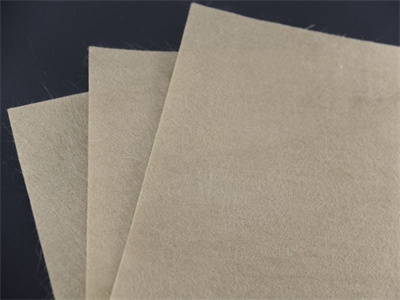

● Nonwoven fabrics have unique structures differing from woven and knitted fabrics, consisting mainly of fiber networks (non-yarn networks).

● By choosing different fiber materials, processing methods, and post-treatment processes, a wide range of nonwoven fabric products with various properties and uses can be produced.

● Applications include medical hygiene and healthcare, home décor and apparel, industrial fabrics, civil engineering and construction, automotive industry, agriculture and horticulture, packaging materials, and more.

5. Huge market potential and significant economic benefits.

● Faster web formation speed, shorter process flow, higher labor productivity, and lower costs compared to dry methods.

● High competitive strength and good economic returns due to higher labor productivity (10-20 times that of dry methods) and lower production costs (60-70% of dry methods).

6. Promotes resource recycling and combats white pollution.

● Additives can enhance biodegradability of disposable products and packaging materials prone to white pollution.

● Functional materials can improve recyclability, reducing recycling costs and facilitating resource reuse while mitigating white pollution.

In summary, wet nonwoven fabric technology is emerging and holds promising prospects in China. Its development aligns with national industrial policies and sustainable development plans. It contributes significantly to increasing labor productivity, reducing production costs, managing environmental pollution, and utilizing resources efficiently, offering important economic and social benefits.