Revolutionizing Aerospace: Innovative Fiber Materials Enhancing Performance and Safety

2024-12-24 14:53

With the continuous advancement of technology, the aerospace industry has become increasingly demanding in terms of material performance, with lightweight, high strength, and heat resistance being key requirements. Advanced fiber materials, with their unique advantages, have found widespread applications in this field. The following are several specific applications of advanced fiber materials in the aerospace industry:

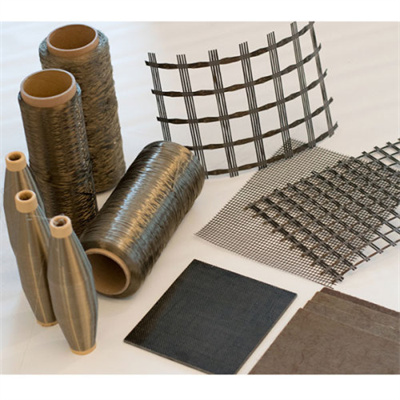

1. Carbon Fiber Composites in Aircraft Structures

n Carbon fiber composites, due to their high specific strength and modulus, have become one of the preferred materials in aircraft manufacturing.

n In next-generation commercial aircraft such as the Boeing 787 and Airbus A350 XWB, the use of carbon fiber composites exceeds 50% and 53%, respectively.

n These materials are widely used in critical components such as the fuselage, wings, and tail, reducing aircraft weight, fuel consumption, and increasing payload capacity and range.

n Their good corrosion resistance and fatigue resistance also extend the service life of aircraft.

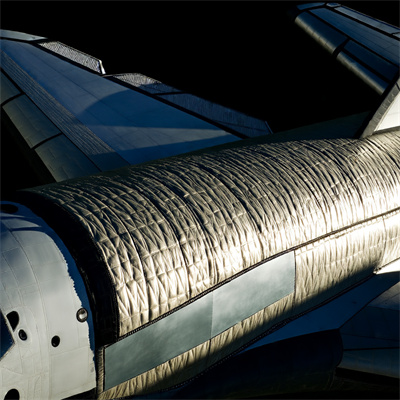

2. Ceramic Fibers in Aerospace Thermal Protection Systems

n Ceramic fibers, with their excellent heat resistance, play a crucial role in the thermal protection systems of aerospace vehicles.

n For example, the heat shield tiles of space shuttles are primarily made of ceramic fiber materials, effectively withstanding the high temperatures generated during reentry into the atmosphere, protecting the internal structure and crew safety.

n Ceramic fibers are also used in the manufacture of high-temperature components such as rocket engine nozzles and combustion chambers, improving engine efficiency and reliability.

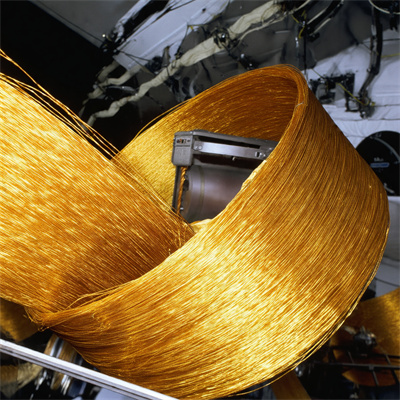

3. Kevlar Fiber in Aerospace Protective Structures

n Kevlar fiber, a high-strength synthetic fiber with excellent impact resistance and wear resistance, is used in the manufacture of protective structures such as aircraft seats and cabin walls, effectively improving the safety of aircraft.

n Kevlar fiber is also used in the manufacture of astronaut protective clothing and helmets, providing excellent protection.

4. Glass Fiber Composites in Aerospace Substructures

n Glass fiber composites, with their good mechanical properties and cost advantages, are widely used in aerospace substructures.

n For example, components such as aircraft cabin doors, fairings, and rudders are often made of glass fiber composites, reducing structural weight while maintaining good formability and weather resistance to meet the diverse needs of aerospace vehicles.

5. Basalt Fiber Composites in Aerospace Applications

n Basalt fiber, a natural mineral fiber with high strength, high modulus, heat resistance, and corrosion resistance, is used in the manufacture of aircraft components such as wings, tail fins, and cabin doors, offering better mechanical properties and environmental performance than traditional materials.

n Basalt fiber is also used in the manufacture of key components such as rocket engine casings, improving the load-bearing capacity and reliability of rockets.

6. Polyimide Fibers in High-Temperature Environments in Aerospace

n Polyimide fibers, a type of high-performance organic fiber with excellent heat resistance, chemical corrosion resistance, and mechanical properties, are used in the manufacture of engine insulation materials and high-temperature filtration materials in the aerospace industry.

n These materials can maintain stable performance in extreme environments, improving engine efficiency and safety.

The application of advanced fiber materials in the aerospace industry not only drives the advancement and development of aircraft technology but also provides more reliable and efficient solutions for human space exploration and transportation improvement. As technology continues to advance and costs gradually decrease, the prospects for the application of advanced fiber materials in the aerospace industry will become even broader.