Wet-Laid Carbon Fiber Nonwoven: The Ultimate Solution for High-Performance Applications

In the rapidly evolving world of advanced materials, wet-laid carbon fiber nonwoven stands out as a revolutionary product, offering unparalleled strength, lightweight properties, and versatility. Designed for industries demanding high-performance solutions, this innovative material is transforming applications in aerospace, automotive, energy, and beyond. In this article, we explore the unique benefits, manufacturing process, and key applications of wet-laid carbon fiber nonwoven—ensuring your business stays ahead of the competition.

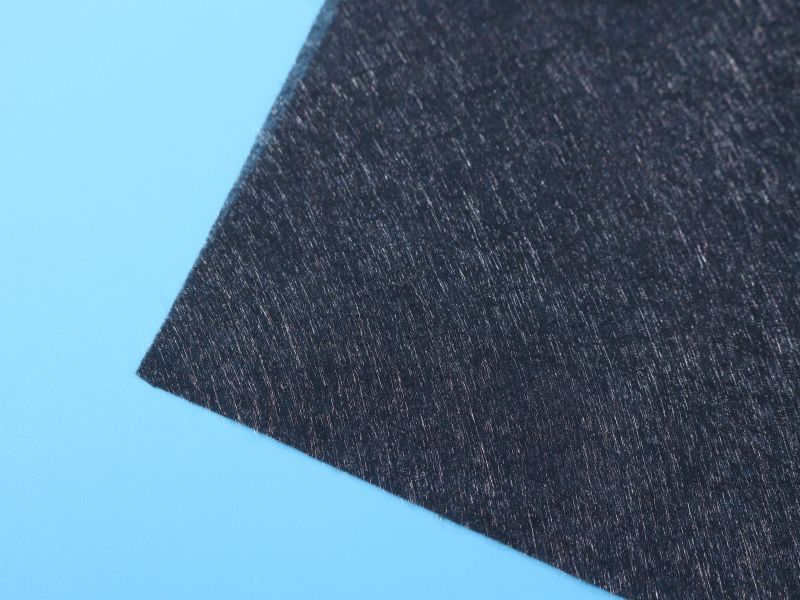

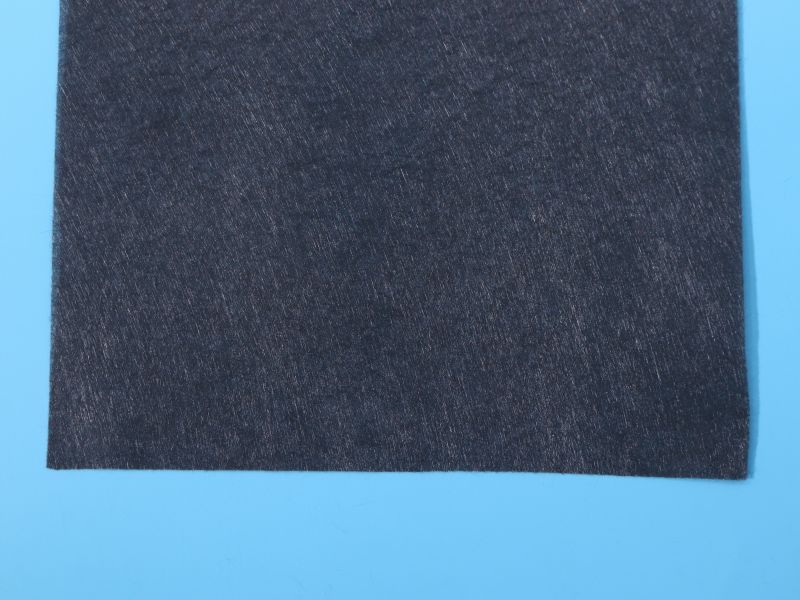

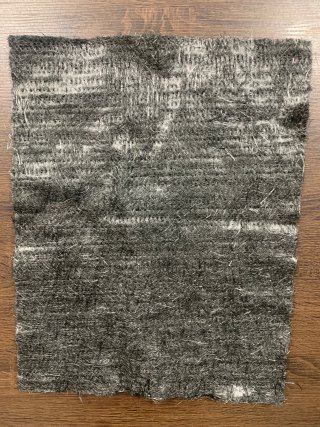

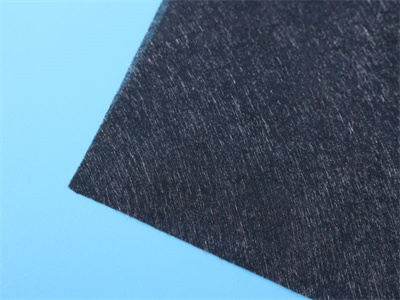

What is Wet-Laid Carbon Fiber Nonwoven?

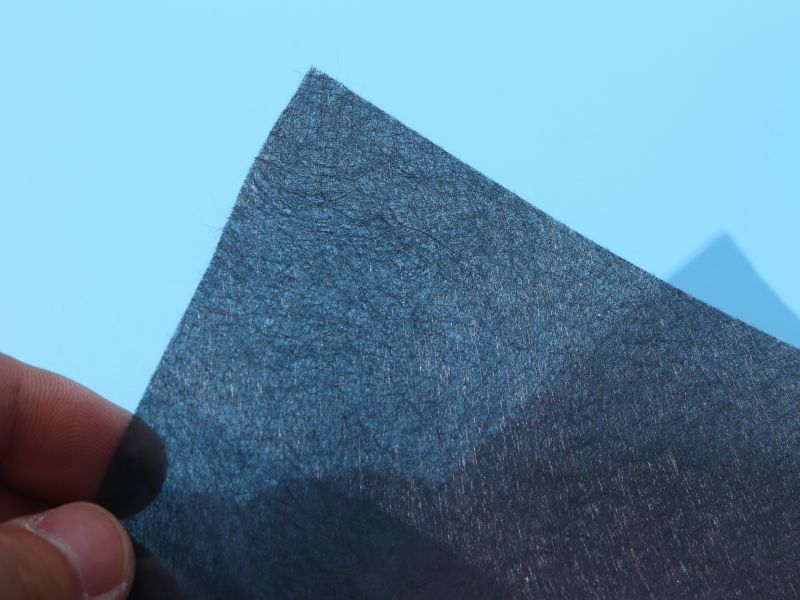

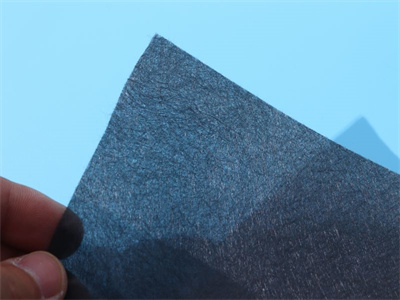

Wet-laid carbon fiber nonwoven is a specialized fabric produced using a unique wet-laid manufacturing process. Unlike traditional weaving methods, this technique disperses carbon fibers evenly in a liquid suspension before forming them into a cohesive, nonwoven sheet. The result is a material with exceptional uniformity, porosity, and mechanical properties, making it ideal for high-stress environments.

Key advantages include:

- Lightweight yet Durable: Perfect for weight-sensitive applications without compromising strength.

- Thermal & Chemical Resistance: Withstands extreme temperatures and corrosive environments.

- Design Flexibility: Easily molded into complex shapes for custom solutions.

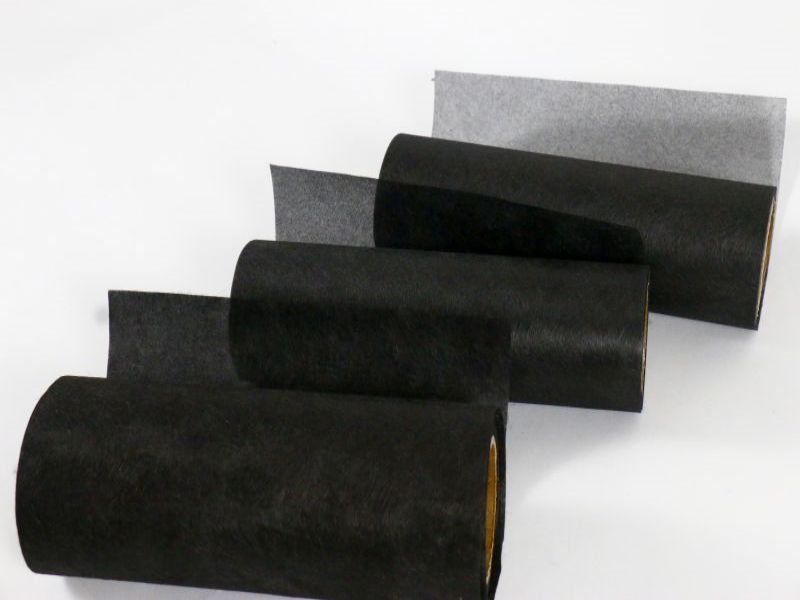

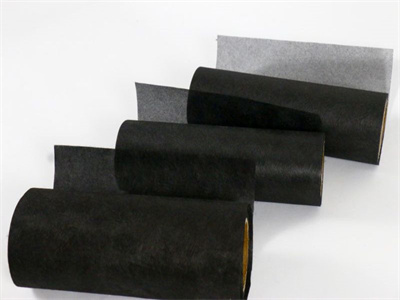

Area Weight | Thickness | Tensile Strength | Moisture Content |

g/m² | mm | N/50mm | % |

6±1 | 0.06±0.01 | 2.5±0.5 | ≤0.28 |

8±1 | 0.08±0.01 | 5.5±0.5 | ≤0.29 |

10±1 | 0.09±0.01 | 5.6±0.5 | ≤0.295 |

15±1 | 0.13±0.01 | 6.9±1 | ≤0.35 |

20±1 | 0.18±0.02 | 11±2 | ≤0.37 |

30±2 | 0.21±0.02 | 16.9±2 | ≤0.38 |

50±2 | 0.38±0.02 | 25.8±0.3 | ≤0.38 |

The Wet-Laid Manufacturing Process: Precision Meets Innovation

The production of wet-laid carbon fiber nonwoven involves cutting-edge technology:

1. Fiber Dispersion: Carbon fibers are mixed with water or solvents to create a homogeneous slurry.

2. Sheet Formation: The slurry is deposited onto a mesh conveyor, allowing liquid to drain and fibers to bond.

3. Drying & Consolidation: The sheet is dried and compressed, enhancing density and structural integrity.

This process ensures minimal fiber damage and optimal alignment, delivering consistent performance across batches—a critical factor for industries like aerospace and automotive manufacturing.

Key Applications of Wet-Laid Carbon Fiber Nonwoven

From cutting-edge technology to everyday innovations, wet-laid carbon fiber nonwoven is driving progress in multiple sectors:

1. Aerospace & Defense

Used in aircraft interiors, drone components, and missile systems, its lightweight nature reduces fuel consumption while meeting stringent safety standards.

2. Automotive Innovation

Electric vehicle (EV) manufacturers leverage this material for battery enclosures and structural reinforcements, enhancing energy efficiency and crash resistance.

3. Energy & Sustainability

In wind turbine blades and hydrogen fuel cells, wet-laid carbon fiber nonwoven improves durability and energy output, supporting global renewable energy goals.

4. Electronics & Thermal Management

Its superior thermal conductivity makes it ideal for heat dissipation in 5G devices, LED lighting, and high-power electronics.

Why Choose Our Wet-Laid Carbon Fiber Nonwoven?

As a leading supplier of wet-laid carbon fiber nonwoven, we prioritize quality, innovation, and sustainability:

- Customizable Solutions: Tailor fiber length, density, and resin compatibility to meet your specs.

- Global Certifications: Compliant with ISO, REACH, and aerospace industry standards.

- Cost-Efficiency: Optimized production processes reduce waste and lead times.

Conclusion: Elevate Your Products with Wet-Laid Carbon Fiber Nonwoven

In a competitive market, wet-laid carbon fiber nonwoven offers a strategic edge—combining advanced engineering with eco-friendly performance. Whether you’re developing next-gen vehicles, renewable energy systems, or high-tech electronics, this material delivers unmatched reliability.

Partner with us to integrate wet-laid carbon fiber nonwoven into your supply chain. Contact our team today for samples, technical data, and customized quotes!