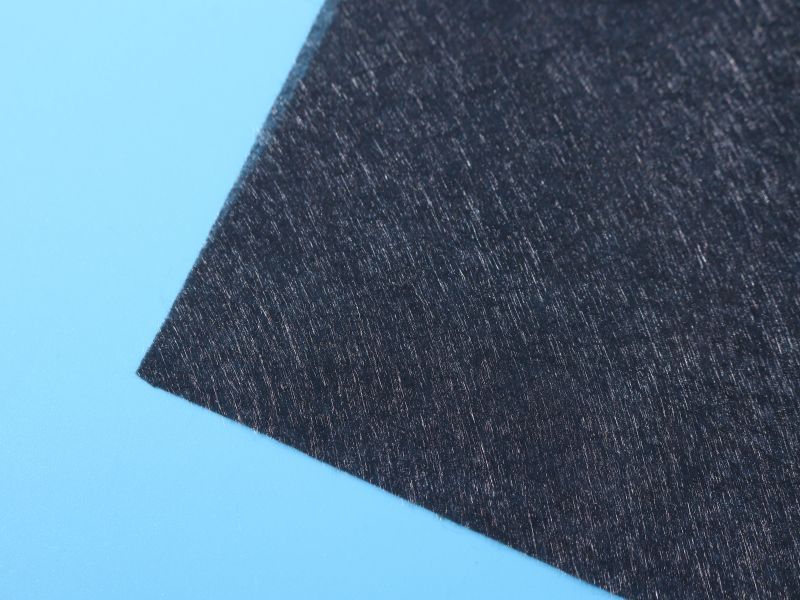

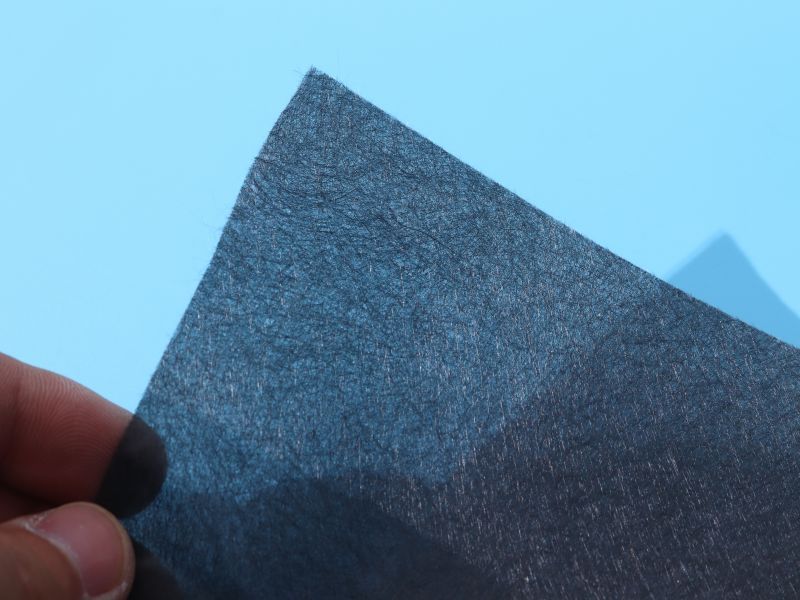

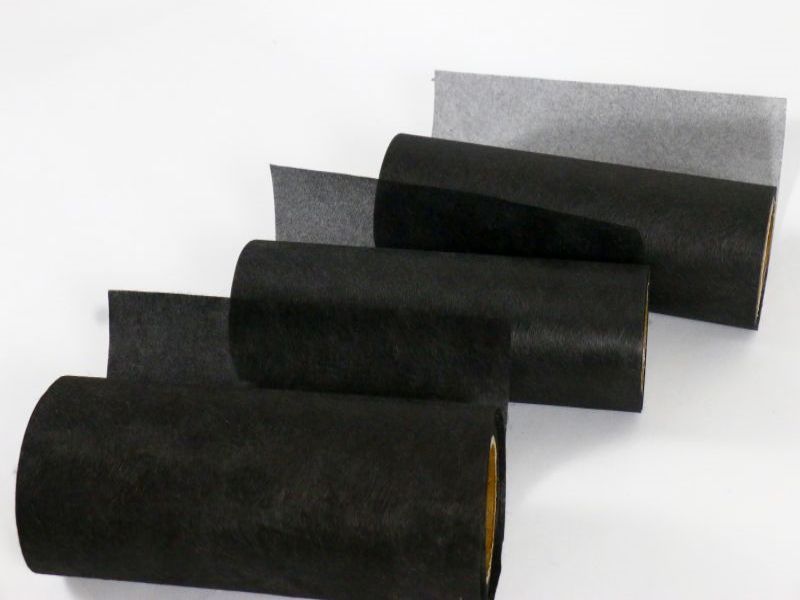

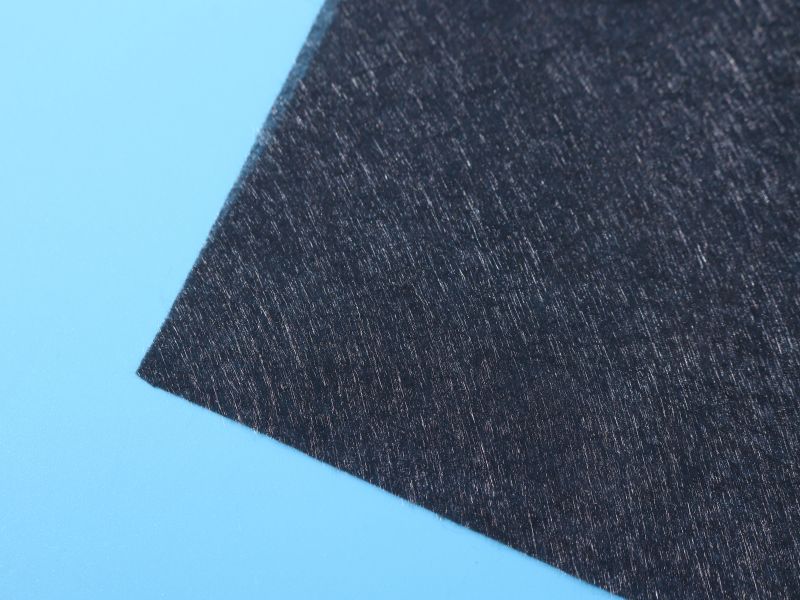

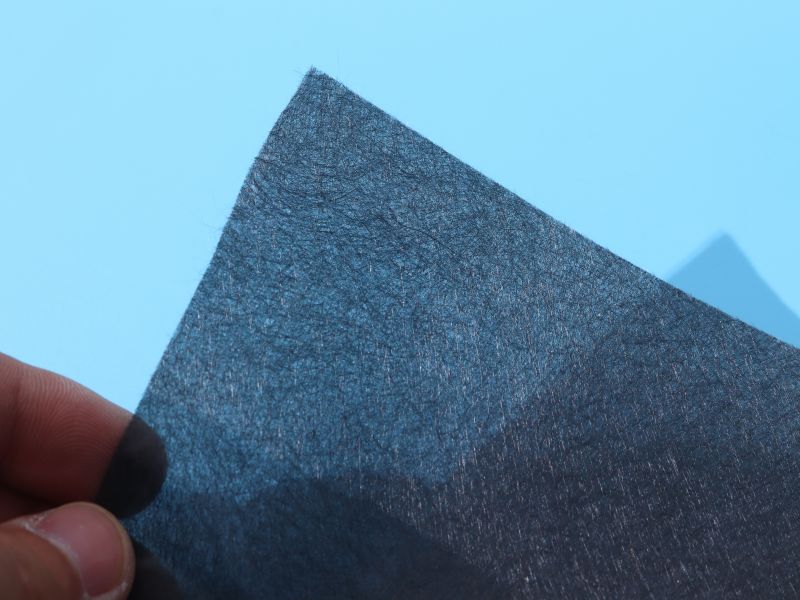

Wet-laid Carbon Fiber Non-Woven Fabric

Wet-laid Carbon Fiber Non-Woven Fabric represents a state-of-the-art composite material that combines the outstanding strength of carbon fiber with the flexibility of non-woven technology. The wet-laid process involves suspending individual carbon fibers in a liquid medium and depositing them uniformly onto a forming wire. This ensures an even distribution and precise control over fiber orientation, which is essential for achieving superior mechanical properties. The resulting fabric is lightweight, durable, and versatile, making it ideal for use in industries such as aerospace, automotive, sports equipment, and construction. Its high tensile strength, customizable properties, and excellent wear resistance make it a top choice for performance-driven applications.

Product Introduction:

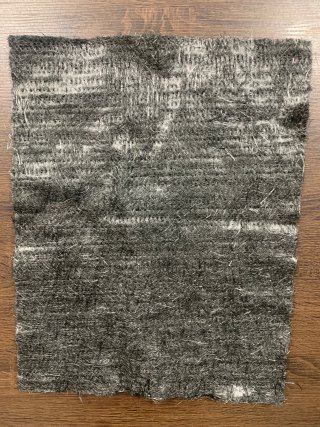

Wet-laid Carbon Fiber Non-Woven Fabric is an innovative material that combines the strength and durability of carbon fiber with the versatility and flexibility of non-woven fabrics. The wet-laid process involves suspending individual fibers in a liquid carrier before depositing them onto a forming wire to create a uniform web. This unique wet-laid method ensures that each strand of carbon fiber is evenly distributed throughout the fabric, resulting in a homogeneous structure. The wet-laid technique also allows for the precise control of fiber orientation and density, which are critical factors in achieving superior mechanical properties.

During the wet-laid manufacturing stage, the carbon fiber is carefully aligned to maximize tensile strength while maintaining the lightweight nature of the final product. This advanced wet-laid process is what sets our carbon fiber non-woven fabric apart from traditional woven materials, making it ideal for a wide range of applications where strength-to-weight ratio is paramount.

Product Applications:

1. Aerospace Components - Due to its exceptional strength and low weight, our wet-laid carbon fiber non-woven fabric is perfect for manufacturing lightweight yet robust aerospace components.

2. Automotive Industry - Carbon fiber composites made using the wet-laid process are utilized in high-performance vehicles to enhance fuel efficiency and structural integrity.

3. Sports Equipment - Our non-woven fabric provides unparalleled stiffness and impact resistance, making it suitable for sports equipment such as tennis rackets and bicycle frames.

4. Construction Materials - Wet-laid carbon fiber non-woven fabric can be used as reinforcement in concrete and other building materials to increase their durability and load-bearing capacity.

Product Features:

1. High Tensile Strength - The wet-laid process ensures that the carbon fiber strands are evenly dispersed, resulting in a material with exceptional tensile strength.

2. Lightweight - Despite its strength, our non-woven fabric is incredibly lightweight, offering a high strength-to-weight ratio.

3. Versatility - The wet-laid method allows for customization of the fabric’s properties, making it adaptable to various applications.

4. Durability - Carbon fiber is known for its longevity, and when combined with the wet-laid process, our fabric offers outstanding resistance to wear and tear.

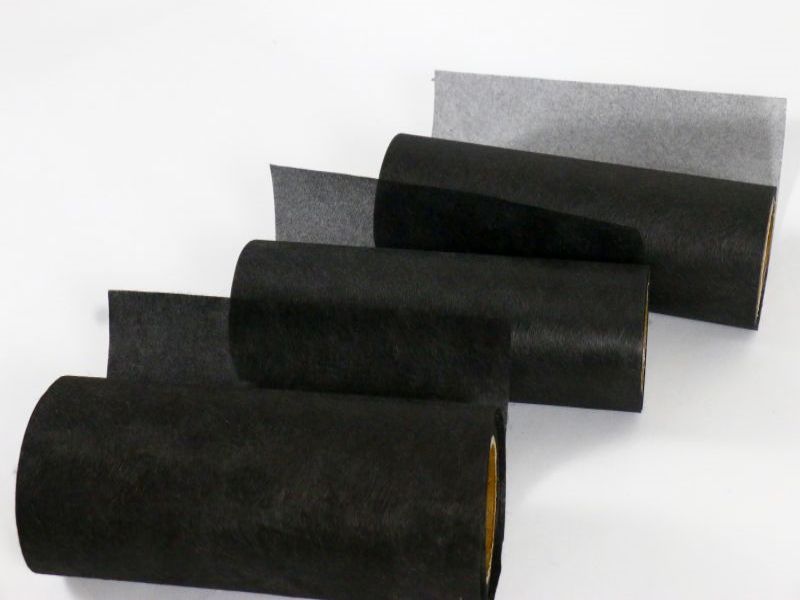

5. Customizable - The wet-laid carbon fiber non-woven fabric can be tailored to specific requirements in terms of thickness, width, and fiber orientation.

| Item Code | Area Weight | Surface Resistance | Binder Content | Moisture Content | Tensile Strength | Thickness |

| BN-005 | 5g/m2 | - | 10%±2% | ≤0.3% | - | 0.05±0.01mm |

| BN-006 | 6g/m2 | - | 10%±2% | ≤0.3% | ≥5N/50mm | 0.06±0.01mm |

| BN-008 | 8g/m2 | - | 10%±2% | ≤0.3% | ≥7N/50mm | 0.08±0.01mm |

| BN-010 | 10g/m2 | ≤15Ω | 10%±2% | ≤0.3% | ≥11N/50mm | 0.09±0.01mm |

| BN-015 | 15g/m2 | ≤8Ω | 10%±2% | ≤0.3% | ≥16N/50mm | 0.15±0.02mm |

| BN-020 | 30g/m2 | ≤6Ω | 10%±2% | ≤0.3% | ≥21N/50mm | 0.20±0.03mm |

| BN-030 | 50g/m2 | ≤4Ω | 10%±2% | ≤0.3% | ≥31N/50mm | 0.30±0.03mm |

| BN-050 | 60g/m2 | ≤3Ω | 10%±2% | ≤0.3% | ≥40N/50mm | 0.50±0.04mm |