Silica Needle Mat: The Ultimate High-Temperature Insulation Material

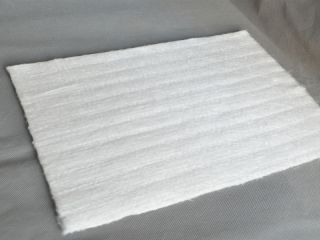

The Silica Needle Mat is a premium-grade insulation product engineered for extreme heat resistance and durability. Composed of 94-96% pure amorphous Silica Fiber, this material undergoes a specialized needling process to create a tightly interlocked Needled Mat structure. Unlike traditional ceramic blankets or rigid boards, its flexible yet robust design allows it to conform to irregular surfaces while maintaining thermal efficiency. Ideal for industries where safety and performance are critical, this mat combines lightweight versatility with industrial-grade resilience.

What Is Silica Needle Mat?

The Silica Needle Mat is a premium-grade insulation product engineered for extreme heat resistance and durability. Composed of 94-96% pure amorphous Silica Fiber, this material undergoes a specialized needling process to create a tightly interlocked Needled Mat structure. Unlike traditional ceramic blankets or rigid boards, its flexible yet robust design allows it to conform to irregular surfaces while maintaining thermal efficiency. Ideal for industries where safety and performance are critical, this mat combines lightweight versatility with industrial-grade resilience.

Core Applications of Silica Needle Mat

The Silica Needle Mat serves as a multi-functional solution across diverse sectors. Its adaptability stems from the unique properties of Silica Fiber, which offers unmatched thermal stability, and the Needled Mat’s mechanical strength. Key industries and uses include:

1. Aerospace & Automotive

● Fireproof insulation for engine compartments and exhaust systems.

● Heat shields in electric vehicle battery modules.

● Thermal protection for aircraft engine components.

2. Industrial Manufacturing

● Lining for furnaces, kilns, and ovens in glass, steel, and foundry industries.

● Insulation for boilers, turbines, and heat exchangers in power plants.

● Gaskets and seals in chemical processing equipment.

3. Construction & Energy

● Fire-resistant barriers in high-rise buildings and tunnels.

● Insulation for solar thermal systems and nuclear facilities.

● Pipe wrapping to prevent heat loss in district heating networks.

4. Specialized Uses

● Protective covers for welding operations.

● Thermal insulation in laboratory equipment.

● Heat management in high-performance electronics.

Technical Advantages of Silica Needle Mat

The Silica Needle Mat outperforms conventional insulation materials due to its innovative design and Silica Fiber composition. Below are its standout features:

1. Superior Thermal Performance

● Withstands continuous temperatures up to 1,800°F (980°C) and short-term spikes up to 2,200°F (1,200°C).

● Low thermal conductivity reduces energy consumption by minimizing heat transfer.

2. Unmatched Flexibility

● The Needled Mat’s non-woven structure allows easy cutting, bending, and wrapping around complex shapes.

● Maintains integrity even after repeated handling or vibration.

3. Chemical & Environmental Resistance

● Silica Fiber is inert to most acids, alkalis, and oils, ensuring longevity in corrosive environments.

● Resists moisture absorption and fungal growth, making it suitable for humid conditions.

4. Safety & Compliance

● Non-combustible and emits negligible smoke or toxic fumes under extreme heat.

● Complies with international standards like ASTM, ISO, and RoHS.

5. Cost-Effective Durability

● The Needled Mat’s reinforced fibers resist tearing, fraying, and compression settling.

● Reduces maintenance costs by extending equipment lifespan.

Comparing Silica Needle Mat to Alternatives

While materials like ceramic fiber blankets or mineral wool offer thermal insulation, the Silica Needle Mat excels in critical areas:

● Versus Ceramic Fiber: Silica-based fibers have higher purity, lower thermal shrinkage, and better resistance to thermal shock.

● Versus Mineral Wool: The Needled Mat is lighter, non-irritating to skin, and provides superior chemical stability.

● Versus Rigid Boards: Its flexibility eliminates installation gaps, improving insulation efficiency.

Installation & Maintenance Tips

To maximize the Silica Needle Mat’s performance:

1. Pre-Installation

● Measure and cut the mat using sharp blades or scissors.

● Wear gloves and masks to avoid minor fiber irritation (though safer than traditional ceramics).

2. Fitting & Securing

● Use high-temperature adhesives or stainless-steel staples for fixation.

● Overlap seams by 1-2 inches to prevent heat leakage.

3. Long-Term Care

● Inspect periodically for wear in high-abrasion zones.

● Replace sections only if physically damaged; the mat retains properties even after prolonged use.

Why Industries Trust Silica Fiber Needled Mat

The Silica Needle Mat has become a go-to solution for engineers and manufacturers globally, thanks to:

● Customizability: Available in multiple thicknesses (5mm–50mm) and densities.

● Sustainability: Produced with minimal binders, it aligns with eco-friendly industrial practices.

● Cost Efficiency: Reduces energy bills by up to 30% compared to uninsulated systems.

Conclusion

The Silica Needle Mat redefines high-temperature insulation with its unique blend of Silica Fiber excellence and Needled Mat practicality. Whether safeguarding aerospace systems, optimizing industrial processes, or enhancing building safety, this material delivers unmatched thermal management, durability, and cost savings. For businesses prioritizing efficiency and reliability, investing in Silica Needle Mat technology is a strategic step toward sustainable growth.