Quartz Felt as a Ceramic Fiber Substitute for Insulation

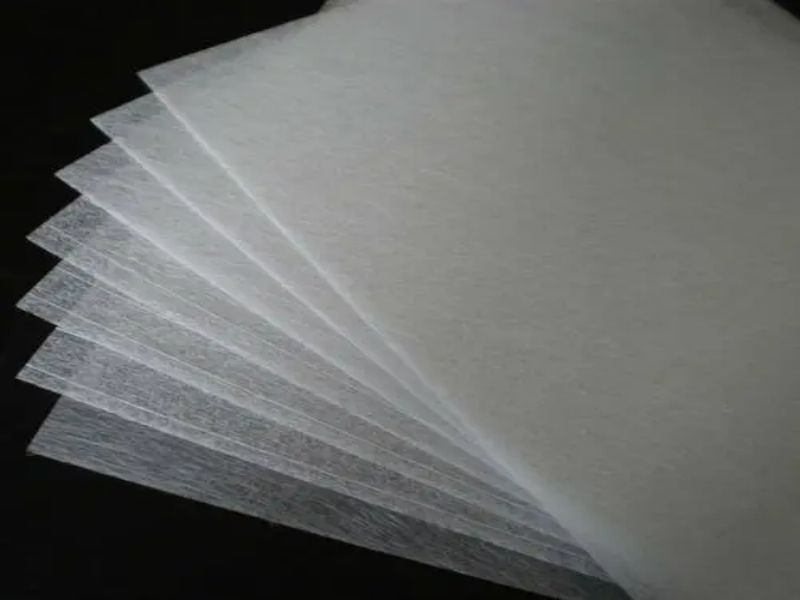

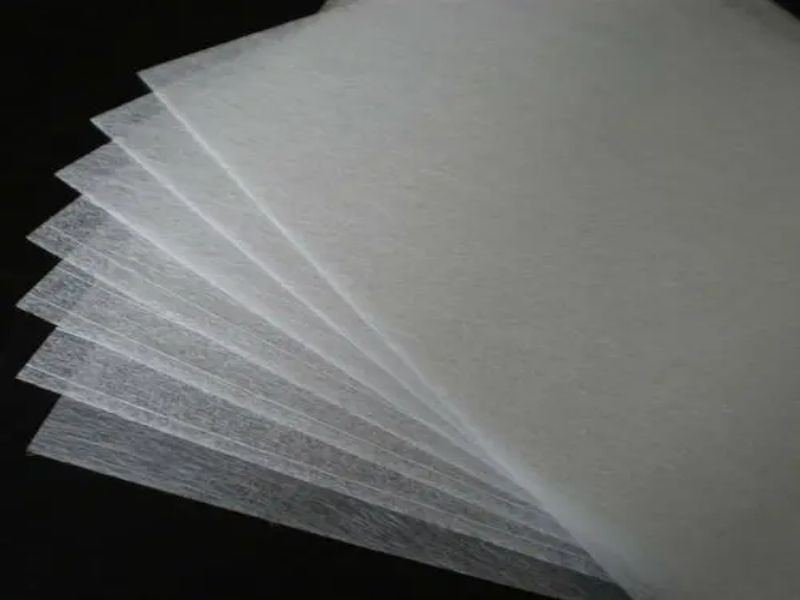

Quartz Felt as a Ceramic Fiber Substitute for Insulation is a cutting-edge thermal insulation material crafted from high-purity quartz fibers. It is specifically designed to replace traditional ceramic fibers, offering superior heat resistance and enhanced durability. This lightweight and flexible material excels in high-temperature applications, ensuring efficient energy retention and reduced heat loss. Quartz Felt is ideal for use in industries such as aerospace, metallurgy, and energy production, where reliable insulation is critical. Its eco-friendly composition, combined with excellent mechanical strength and non-combustible properties, makes it a trusted choice for advanced insulation needs in demanding environments.

Quartz Felt as a Ceramic Fiber Substitute for Insulation

Specification | Quartz Fiber Nonwoven | Quartz Fiber Veil |

Thickness | 0.1 - 0.5 mm | 0.05 - 0.2 mm |

Weight | 100 - 200 g/m² | 50 - 150 g/m² |

Temperature Resistance | Up to 1050°C | Up to 1050°C |

Chemical Resistance | Excellent | Excellent |

Tensile Strength | High | High |

Applications | Aerospace, Automotive, Chemical Processing | Aerospace, Automotive, Chemical Processing |

Environmental Impact | Low | Low |

1. Product Overview

Quartz Felt as a Ceramic Fiber Substitute for Insulation is an advanced thermal insulation material designed to provide superior performance in demanding environments. Made from high-purity quartz fibers, this innovative product offers exceptional heat resistance, low thermal conductivity, and a lightweight structure, making it an ideal alternative to traditional ceramic fibers. Engineered for reliability and versatility, Quartz Felt ensures durability and safety in a variety of industrial and commercial applications.

2. Product Applications

Quartz Felt as a Ceramic Fiber Substitute for Insulation is suitable for a wide range of insulation needs:

· High-temperature industries: Provides effective thermal insulation for kilns, furnaces, and ovens.

· Aerospace and defense: Serves as a protective barrier for thermal management in critical equipment.

· Automotive sector: Used in exhaust systems and heat shields to enhance energy efficiency.

· Electronics manufacturing: Ensures temperature stability in precision devices.

· Energy sector: Utilized in boilers and turbines for improved heat retention and energy savings.

3. Key Features

The unique properties of Quartz Felt as a Ceramic Fiber Substitute for Insulation include:

· Exceptional heat resistance: Withstands temperatures up to 1200°C without degradation.

· Low thermal conductivity: Minimizes heat loss for improved energy efficiency.

· Eco-friendly composition: Free from harmful substances and recyclable.

· Lightweight and flexible: Easy to handle, cut, and install for diverse insulation projects.

· Durable structure: Resistant to chemical corrosion and mechanical wear.

· Non-combustible: Enhances fire safety in high-risk environments.

Quartz Felt as a Ceramic Fiber Substitute for Insulation is the ultimate solution for industries seeking a sustainable and effective insulation material that outperforms traditional options.