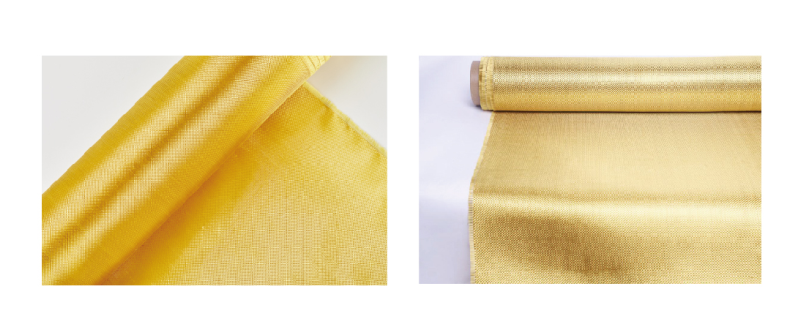

High Sealing Polyimide Fiber For Webbing Packaging Materials

High-seal polyimide fibers for webbing packaging materials are ideal candidates for high-temperature seals and packaging.

When higher levels of chemical resistance are required, webbing packaging materials made of high-sealing polyimide fibers can be impregnated with lubricants and PTFE dispersions.

The sealing temperature of new automobile oil filters is within the range of 250°C, and heat-stable webbing packaging materials with high-sealing polyimide fiber can be used.

1. Product Introduction

The high-sealing polyimide fiber used for webbing packaging materials is lightweight, high-strength, has excellent dielectric properties, good bonding interface with resin, and extremely low expansion coefficient. It is widely used.

2.Product Parameter

| No. | Breaking Strength | Initial Modulus | Elongation | ||

| GPa | cN/dtex | GPa | cN/dtex | % | |

| BMT-10 | 0.6-0.8 | 4.2-5.6 | 3-10 | 21-69 | 5-30 |

| BMT-02 | 2.4-2.9 | 16.7-20.1 | 90-130 | 625-902 | ≥2.5 |

| BMT-2S | 2.4-2.9 | 16.7-20.1 | ≥130 | ≥902 | ≥1.5 |

| BMT-10S | 2.9-3.4 | 20.1-23.6 | 90-130 | 625-902 | ≥2.5 |

| BMT-35 | 2.9-3.4 | 20.1-23.6 | ≥130 | ≥902 | ≥1.5 |

| BMT-30S | 3.4-3.9 | 23.6-27.1 | 90-130 | 625-902 | ≥2.5 |

| ITEM | INDEX |

| Water absorption | <1% |

| Hydrolysis resistance | Excellent |

| Acid resistance | Excellent |

| Alkali resistance | Poor |

| Solvent resistance | Excellent |

| Ultraviolet resistance | Excellent |

| Dielectric properties | Excellent |

| Thermal conductivity | <0.03W/(M.K) |

| Coefficient of thermal expansion | <-0.3%(250℃*15min) |

| Creep resistance | Excellent |

| Wear resistance | Excellent |

| Glass transition temperature | 320℃~410℃ |

| Long-term use temperature | <350℃ |

| Density | 1.44g/cm3 |

| Limiting oxygen index | >38 |

3. Product Feature

High-sealing polyimide fiber for webbing packaging materials has:

High strength and high modulus: breaking strength can reach 4.6GPa;

High-temperature resistance: The initial decomposition temperature of high-sealing polyimide fiber used in webbing packaging materials is generally around 500°C. Polyimide synthesized from biphenyl dianhydride and p-phenylenediamine has a thermal decomposition degree of 600°C;

Low-temperature resistance: The high-sealing polyimide fiber used for webbing packaging materials has excellent low-temperature resistance and will not be brittle even in -269°C liquid nitrogen;

Radiation resistance is very good;

Excellent dimensional stability;

Biocompatibility: The high-sealing polyimide fiber used for webbing packaging materials is non-biotoxic and can withstand thousands of sterilizations;

The high-sealing polyimide fiber used for webbing packaging materials has good dielectric properties, with a dielectric constant of around 3.4;

The high-sealing polyimide fiber used for webbing packaging materials is a self-extinguishing polymer: with a low smoke rate.

4. Product Details

The limiting oxygen index (LOI) of the high-sealing polyimide fiber used for webbing packaging materials is as high as 38%. It will be carbonized without melting droplets when exposed to high-temperature open flames, self-extinguishing when removed from the fire, and non-toxic.

The high-sealing polyimide fiber used in webbing packaging materials can ensure that the fabric has good mechanical properties and dimensional stability in high and low-temperature environments and has good thermal oxidation resistance, corrosion resistance, and UV resistance.

High-sealing polyimide fiber for webbing packaging materials is an ideal material for making flame-retardant high-temperature materials.