Lightweight Polyimide Fibers For Transportation

Internal materials for aircraft and other transportation vehicles, including various structurally rigid three-dimensional elements, can be made of lightweight polyimide fibers for transportation;

For example, in airplanes and high-speed trains, lightness is a very important factor. These low-density, hard and fire-resistant lightweight polyimide fibers for transportation can replace traditional materials.

1. Product Introduction

Lightweight polyimide fiber for transportation has excellent flame retardant properties and a limiting oxygen index of >38%, making it a non-combustible fiber;

Lightweight polyimide fiber for transportation is resistant to high and low temperatures, can be used for a long time below 300°C, has a thermal decomposition temperature exceeding 567°C, and is not brittle in liquid nitrogen at -269°C;

The lightweight polyimide fiber used for transportation does not melt when carbonized at high temperatures, and the smoke density is 1/200 of the Chinese aviation standard;

Lightweight polyimide fiber for transportation is used for thermal insulation and warmth, with a thermal conductivity of only 0.03W/m·℃, which is equivalent to air;

Lightweight polyimide fiber for transportation also has excellent properties such as insulation, weather resistance, acid and alkali resistance, radiation resistance, and UV resistance. It also has a cashmere-like feel, good spinnability, and skin-friendliness;

Lightweight polyimide fiber for transportation is naturally antibacterial and has a much better effect than bamboo fiber;

Lightweight polyimide fiber for transportation has a natural far-infrared healthcare function, with a normal emissivity as high as 0.88.

2.Product Parameter

| No. | Breaking Strength | Initial Modulus | Elongation | ||

| GPa | cN/dtex | GPa | cN/dtex | % | |

| BMT-10 | 0.6-0.8 | 4.2-5.6 | 3-10 | 21-69 | 5-30 |

| BMT-02 | 2.4-2.9 | 16.7-20.1 | 90-130 | 625-902 | ≥2.5 |

| BMT-2S | 2.4-2.9 | 16.7-20.1 | ≥130 | ≥902 | ≥1.5 |

| BMT-10S | 2.9-3.4 | 20.1-23.6 | 90-130 | 625-902 | ≥2.5 |

| BMT-35 | 2.9-3.4 | 20.1-23.6 | ≥130 | ≥902 | ≥1.5 |

| BMT-30S | 3.4-3.9 | 23.6-27.1 | 90-130 | 625-902 | ≥2.5 |

| ITEM | INDEX |

| Water absorption | <1% |

| Hydrolysis resistance | Excellent |

| Acid resistance | Excellent |

| Alkali resistance | Poor |

| Solvent resistance | Excellent |

| Ultraviolet resistance | Excellent |

| Dielectric properties | Excellent |

| Thermal conductivity | <0.03W/(M.K) |

| Coefficient of thermal expansion | <-0.3%(250℃*15min) |

| Creep resistance | Excellent |

| Wear resistance | Excellent |

| Glass transition temperature | 320℃~410℃ |

| Long-term use temperature | <350℃ |

| Density | 1.44g/cm3 |

| Limiting oxygen index | >38 |

3. Product Feature

Lightweight polyimide fiber for transportation has oxidation resistance and low water absorption.

Lightweight polyimide fiber for transportation has good spinnability, permanent flame retardancy, dimensional stability and safety, and extremely low thermal conductivity.

Lightweight polyimide fibers for transportation are also reinforcements for advanced composite materials.

Lightweight polyimide fiber for transportation also has the advantages of high elastic modulus, radiation resistance, and lightweight.

4. Product Details

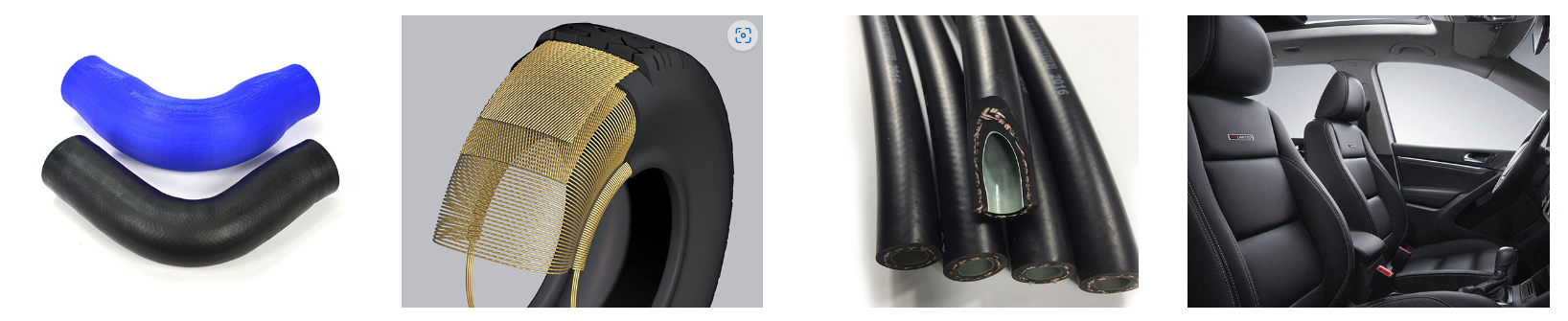

Lightweight polyimide fiber for transportation has the characteristics of lightweight, high strength, high toughness, temperature resistance, flame retardant, and fatigue resistance. Lightweight polyimide fiber for transportation can be used in actuators, tire cords, and brakes It helps improve the safety and durability of various vehicle components including passenger cars, light trucks, and professional racing cars.