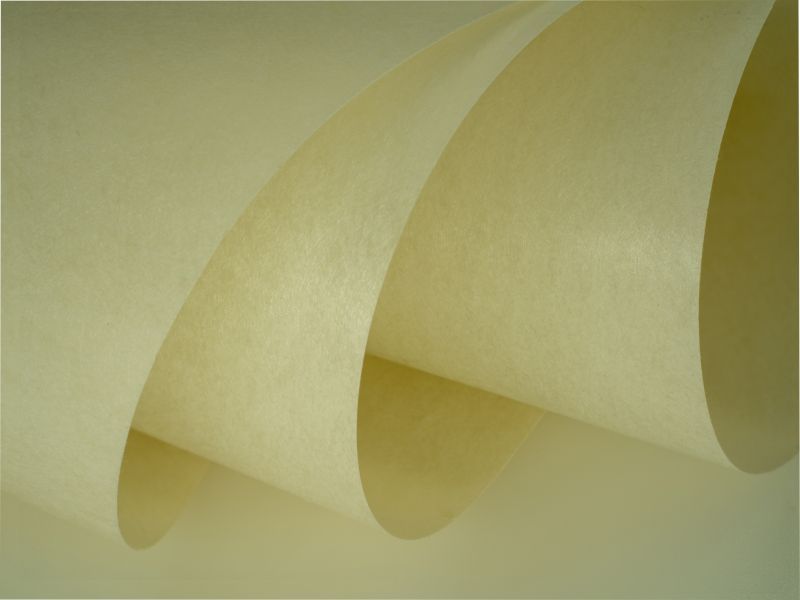

Chemical Resistance PPS Fiber Veil For Battery

The chemical resistant PPS fiber veil for batteries has excellent heat resistance, insulation, chemical resistance, and electrical performance, which is in line with the requirements for materials in the field of lithium batteries. It is an "intimate partner" of lithium batteries. Applied to microelectronics technology characterized by small size, light weight, high reliability, and fast working speed.

1. Product Introduction

Chemical resistance for batteries PPS fiber veil has super high-temperature resistance, stable size and not easy to deform, electrical properties, chemical corrosion resistance, fire retardant, excellent electrical insulation performance, and good arc resistance.

Chemical resistance PPS fiber veil for batteries has the advantages of excellent heat resistance, hard and brittle, high crystallinity, flame retardant, good thermal stability, high mechanical strength, excellent electrical properties, etc., and strong chemical corrosion resistance.

Chemical resistance for batteries PPS fiber veil is one of the most heat-resistant varieties in engineering plastics. The thermal deformation temperature of glass fiber-modified materials is generally greater than 260 degrees, and its chemical resistance is second only to polytetrafluoroethylene.

2. Product Feature

Super high-temperature resistance,

Dimensionally stable and not easy to deform,

electrical properties,

chemical resistance,

fire retardant,

Excellent electrical insulation performance,

Good arc resistance

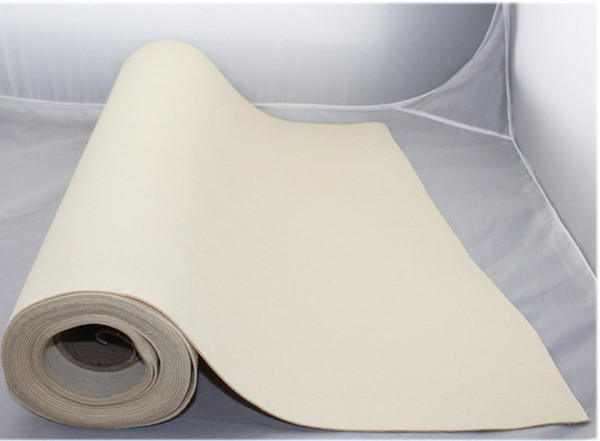

3. Product Details

The chemical-resistant PPS fiber veil for batteries is quite suitable for the application of new energy lithium battery covers. Chemical resistance for batteries The PPS fiber veil has excellent electrolyte resistance, and has good bonding performance with aluminum poles and copper poles, making MIM nano-injection molding applied in power battery sealing rings, which is the best choice for lithium battery sealing rings preferred.

The application of the chemical-resistant PPS fiber veil for batteries in the NMT process of new energy batteries not only realizes the integration of metal and plastic structures, improves the metal texture, simplifies product components, makes products light, thin, and small, but more importantly, reduces The number of parts is reduced, and the loss of cross-sectional area is reduced.

Chemical-resistant PPS fiber veil for batteries has the characteristics of high-temperature resistance, low-temperature resistance, stable size, good insulation performance, and excellent battery thermal stress cycle. Adding an appropriate amount of barium sulfate can be used as a thermally conductive insulating shielding material for new energy vehicles.