Wet-laid Aramid Nonwoven: High-Performance Material for Extreme Conditions

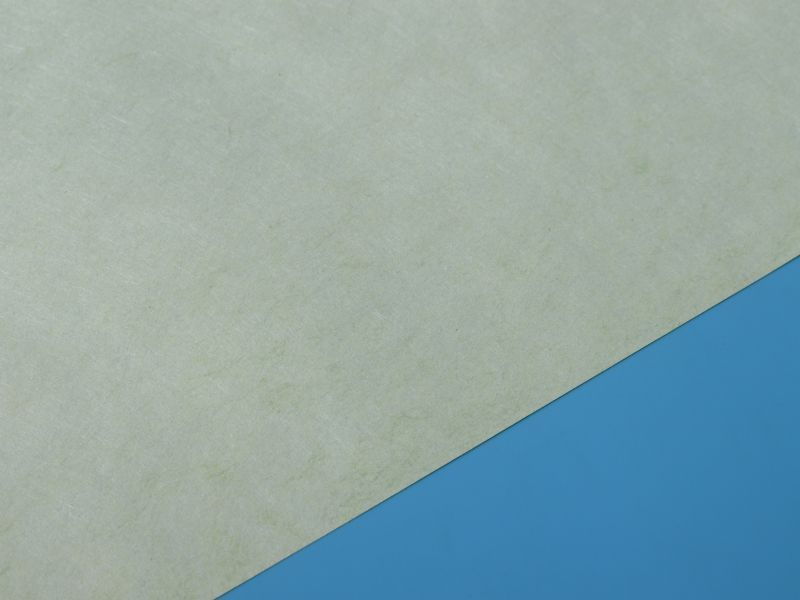

In the realm of advanced industrial materials, Wet-laid Aramid Nonwoven stands out as an engineered solution combining exceptional thermal stability and mechanical strength. This innovative material leverages the unique properties of aramid fibers through a specialized wet-lay process, delivering uniform thickness and density for demanding applications.

In the realm of advanced industrial materials, Wet-laid Aramid Nonwoven stands out as an engineered solution combining exceptional thermal stability and mechanical strength. This innovative material leverages the unique properties of aramid fibers through a specialized wet-lay process, delivering uniform thickness and density for demanding applications.

Key Technical Advantages

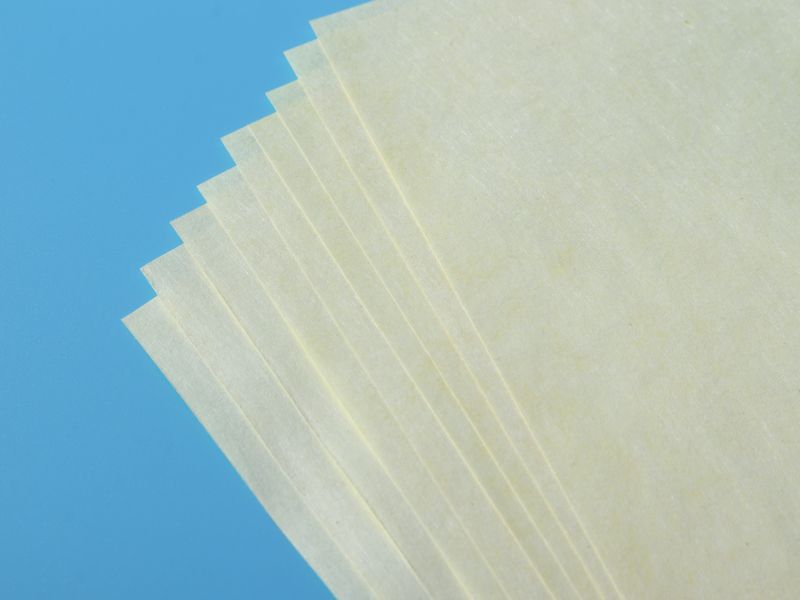

1. Precision Thickness Control

With nominal thickness ranging from 0.05mm (2mil) to 0.76mm (30mil), Wet-laid Aramid Nonwoven offers 9 standardized grades to meet diverse industrial requirements. The material maintains dimensional consistency with maximum 3.5% shrinkage at 300℃ (per IEC60819-2:2002), ensuring reliability in high-temperature environments.

2. Superior Tensile Performance

Tested under GB/T12914-2008 standards:

- MD tensile strength scales from 41N/cm (2mil) to 650N/cm (30mil)

- CD tensile strength progresses from 17N/cm to 450N/cm

This bidirectional reinforcement makes Wet-laid Aramid Nonwoven ideal for load-bearing composites.

3. Optimized Weight-Density Ratio

Achieving 0.79-1.0g/cc density with basis weights from 41.5g/m² to 710g/m² (GB/T451.2-2002), the material provides exceptional strength-to-weight characteristics.

Critical Application Parameters

Nominal Thickness | mil | 2 | 3 | 5 | 7 | 10 | 12 | 15 | 20 | 30 | Testing standard |

mm | 0.05 | 0.08 | 0.13 | 0.18 | 0.25 | 0.3 | 0.38 | 0.51 | 0.76 | ||

Typical Thickness | mm | 0.052 | 0.078 | 0.13 | 0.18 | 0.255 | 0.29 | 0.38 | 0.515 | 0.765 | GB/T451.3-2002 |

Basis Weight | g/m2 | 41.5 | 63 | 116 | 170 | 252 | 291 | 376 | 510 | 710 | GB/T451.2-2002 |

Density | g/cc | 0.79 | 0.8 | 0.9 | 0.94 | 0.99 | 1 | 0.99 | 1 | 0.93 |

|

Tensile Strength N/cm | MD | 41 | 66 | 130 | 200 | 290 | 340 | 420 | 500 | 650 | GB/T12914-2008 |

CD | 17 | 29 | 60 | 75 | 120 | 155 | 250 | 345 | 450 | ||

Elongation% | MD | 7.5 | 9.5 | 10.5 | 11.5 | 11.5 | 10.5 | 12 | 13 | 13 | |

CD | 7 | 9.5 | 11.5 | 12.5 | 13.5 | 10.5 | 13 | 13 | 12 | ||

Tear Strength N | MD | 0.65 | 1.05 | 2.2 | 3.5 | 5 | 6.5 | 10 | 13 | N/A | GB/T455-2002 |

CD | 1.1 | 2.05 | 3.8 | 4.8 | 6 | 8 | 13.5 | 16 | N/A | ||

Shrinkage at 300℃ % | MD | 3.5 | 3.5 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | IEC60819-2:2002 |

CD | 3 | 3 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 2 | 2 |

Industry Applications

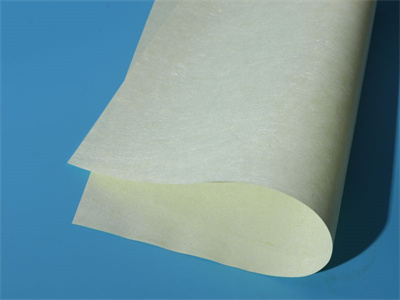

1. Electrical Insulation

The 300℃ thermal stability and UL94 V-0 flame rating make Wet-laid Aramid Nonwoven perfect for motor slot liners and transformer insulation.

2. Aerospace Composites

With MD tensile strength reaching 650N/cm in 30mil grade, the material serves as lightweight reinforcement for aircraft interior panels.

3. Protective Equipment

The 710g/m² high-density variant is being adopted in next-generation firefighter gear for its combination of thermal protection and flexibility.

Why Choose Our Wet-laid Aramid Nonwoven?

- Customizable thickness from 2mil to 30mil

- Strict compliance with GB/T and IEC standards

- Batch-to-batch consistency guaranteed

- Supported by technical datasheets and material safety reports