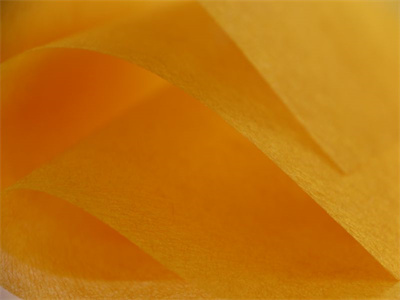

Polyimide Non-Woven Fabric

Polyimide non-woven fabric is an advanced engineered material renowned for its exceptional thermal stability, chemical resistance, and mechanical strength. Made from high-purity polyimide polymers, this fabric is designed to withstand extreme environments while maintaining flexibility and durability. Ideal for industries requiring reliability under stress, polyimide non-woven fabric combines lightweight properties with robust performance, making it a versatile solution for specialized applications.

Introduction to Polyimide Non-Woven Fabric

Polyimide non-woven fabric is an advanced engineered material renowned for its exceptional thermal stability, chemical resistance, and mechanical strength. Made from high-purity polyimide polymers, this fabric is designed to withstand extreme environments while maintaining flexibility and durability. Ideal for industries requiring reliability under stress, polyimide non-woven fabric combines lightweight properties with robust performance, making it a versatile solution for specialized applications.

Density | 1.4g/cm³ |

Tensile Strength | 340 MPa (Nonwoven), 260 MPa (Veil) |

Thermal Stability | Up to 400°C |

Electrical Insulation | Excellent (>1000 V/mil) |

Chemical Resistance | Resistant to common solvents and acids |

Moisture Absorption | <1.2% |

Key Applications of Polyimide Non-Woven Fabric

Polyimide non-woven fabric is widely used across industries due to its unique properties. Key applications include:

1. Aerospace: Thermal insulation for spacecraft and aircraft components.

2. Electronics: Protective layers in batteries, circuit boards, and flexible electronics.

3. Industrial Manufacturing: Heat-resistant gaskets, seals, and filtration systems.

4. Automotive: Lightweight insulation for engines and electric vehicles.

5. Protective Gear: Fire-resistant clothing and safety equipment.

These diverse uses highlight the adaptability of polyimide non-woven fabric in high-temperature and chemically harsh environments.

Notable Features and Benefits

Polyimide non-woven fabric stands out for its:

1. Extreme Heat Resistance: Performs reliably at temperatures exceeding 300°C without degrading.

2. Chemical Inertness: Resists acids, solvents, and oils, ensuring longevity in corrosive settings.

3. Electrical Insulation: Provides excellent dielectric properties for electronic applications.

4. Lightweight and Flexible: Easy to handle and integrate into complex designs.

5. Low Outgassing: Ideal for vacuum environments, minimizing contamination risks.

Why Choose Polyimide Non-Woven Fabric?

For industries prioritizing safety, efficiency, and durability, polyimide non-woven fabric delivers unmatched performance. Its ability to endure extreme conditions while remaining lightweight and adaptable makes it a top choice for engineers and designers. Whether used in cutting-edge technology or traditional manufacturing, this material ensures long-term reliability and cost-effectiveness.

By integrating polyimide non-woven fabric into your projects, you invest in a high-performance solution built to meet the challenges of modern industrial demands. Explore its potential today to elevate your product's capabilities.