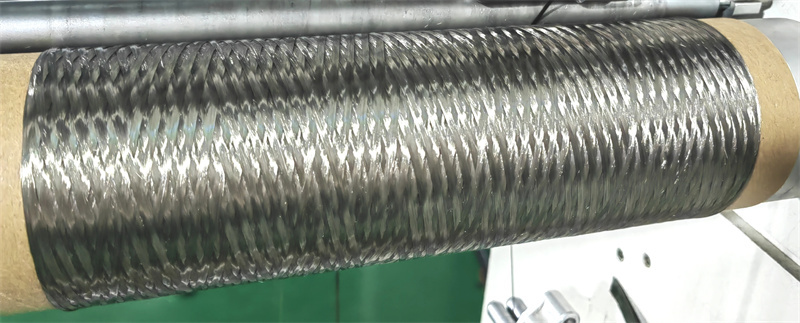

Metal Coated Carbon Fiber

Metal-coated carbon fiber is a cutting-edge composite material that combines the lightweight, high-strength properties of carbon fiber with the enhanced durability and functionality of a metallic coating. By bonding metals like nickel, copper, or aluminum to carbon fiber surfaces, this hybrid material delivers superior performance for industries requiring strength, conductivity, and corrosion resistance. Ideal for high-tech applications, metal-coated carbon fiber bridges the gap between traditional metals and modern composites.

Product Introduction

Metal-coated carbon fiber is a cutting-edge composite material that combines the lightweight, high-strength properties of carbon fiber with the enhanced durability and functionality of a metallic coating. By bonding metals like nickel, copper, or aluminum to carbon fiber surfaces, this hybrid material delivers superior performance for industries requiring strength, conductivity, and corrosion resistance. Ideal for high-tech applications, metal-coated carbon fiber bridges the gap between traditional metals and modern composites.

Item | Test standard | Unit | Classic value | |

Mechanical Properties | Tensile strength | ISO11566 | MPa | 3000 |

Tensile modulus | ISO11566 | GPa | 160 | |

Enlongation at break | ISO11566 | % | 1.3 | |

| ||||

Electrical property | Resistivity | QJ3074 | Ω.cm | 8.23*10-5 |

| ||||

Others | Bulk density | ISO10119 | g/cm3 | 3.2 |

Linear density | ISO11566 | g/km | 1630 | |

Tow | ISO11566 | ends | 12000 | |

Filament diameter |

| μm | 7.3 | |

Coating thickness |

| μm | 0.3 | |

Nickel content |

| % | 50 | |

Cross-sectional area |

| mm2/tow | 0.55 | |

Twist |

|

| none | |

Key Applications of Metal-Coated Carbon Fiber

This versatile material is widely used across industries due to its unique properties:

1. Aerospace: Lightweight structural components, electromagnetic shielding, and thermal management systems.

2. Automotive: Reinforced parts for electric vehicles (EVs), battery components, and heat-resistant elements.

3. Electronics: Conductive substrates, antennas, and circuit board reinforcements.

4. Sports Equipment: Durable, high-performance gear like bicycle frames and racing helmets.

5. Industrial Machinery: Wear-resistant coatings and components for harsh environments.

Standout Features of Metal-Coated Carbon Fiber

1. Lightweight Strength: Retains carbon fiber’s exceptional strength-to-weight ratio while adding metal’s rigidity.

2. Enhanced Conductivity: The metal layer improves electrical and thermal conductivity, ideal for energy-efficient systems.

3. Corrosion Resistance: Protects against oxidation and chemical damage, extending product lifespan.

4. Temperature Resilience: Performs reliably in extreme heat or cold, suitable for demanding applications.

5. Design Flexibility: Customizable coatings and fiber weaves to meet specific project requirements.

Why Choose Metal-Coated Carbon Fiber?

For industries prioritizing innovation and efficiency, metal-coated carbon fiber offers a future-proof solution. Its hybrid design addresses limitations of standalone metals or carbon fiber, making it a go-to material for advanced engineering challenges. Whether improving product performance or reducing energy consumption, this material delivers unmatched value.

Integrate metal-coated carbon fiber into your next project to leverage its transformative benefits. Explore how this material can elevate your applications while meeting modern sustainability and performance standards.