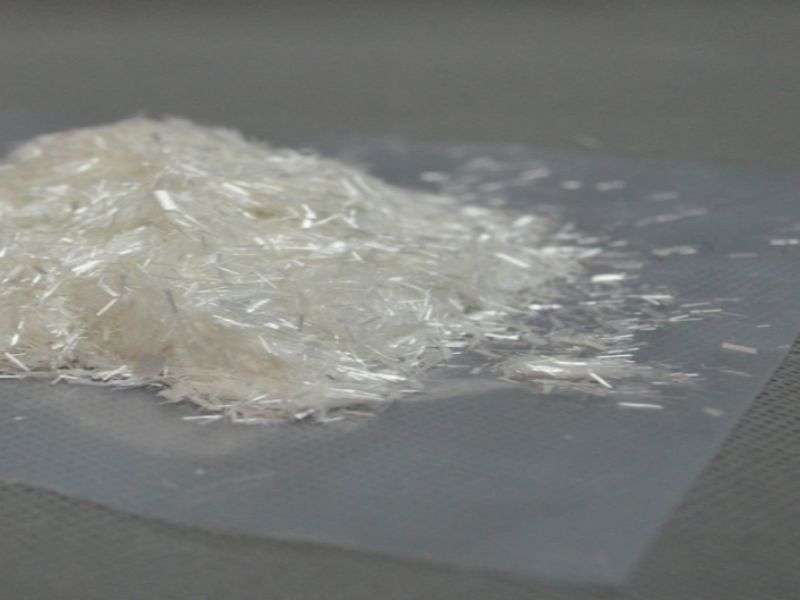

12mm Quartz Fiber Chopped Strands For Ablation

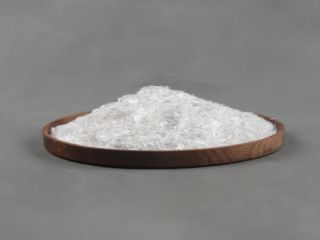

12mm quartz fiber chopped strands for ablation have good bundling properties and low lint content.

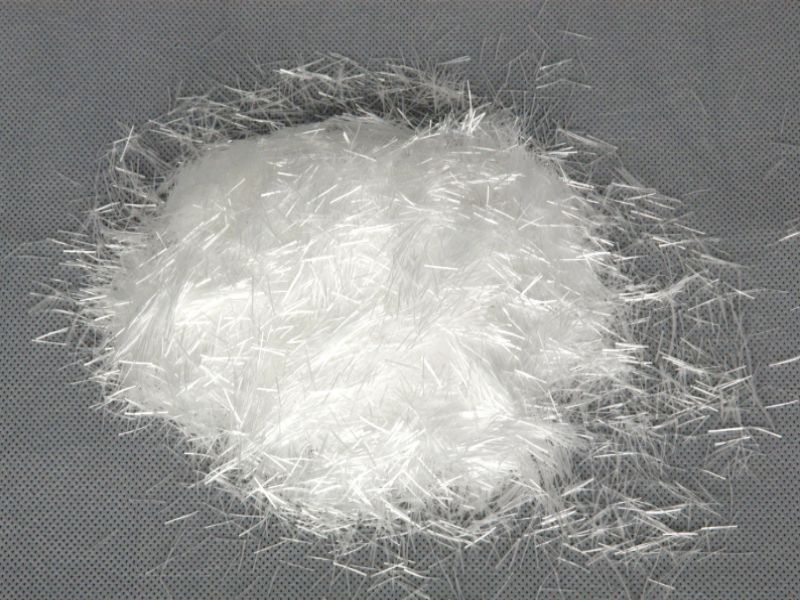

12mm quartz fiber chopped strands for ablation have consistent diameters, high fiber content, uniform fiber length, and no lint, and the fibers maintain good fluidity before being dispersed.

12mm quartz fiber chopped strands for ablation do not generate static electricity, are resistant to ultra-high temperatures, have good toughness and tensile strength, and have high impact strength.

1. Product Introduction

12mm quartz fiber chopped strands for ablation can be used as ablation materials, molds for injection molding or compression molding, reinforcing materials for ceramics, etc.

12mm quartz fiber chopped strands for ablation are heat-resistant, corrosion-resistant, and flexible. It has high strength retention, dimensional stability, thermal shock resistance, chemical stability, light transmittance, and electrical insulation at high temperatures.

2. Product Parameter

| Model | Length(mm) |

| SR104-3 | 3 |

| SR104-6 | 6 |

| SR104-9 | 9 |

| SR104-12 | 12 |

| SR104-20 | 20 |

3. Product performance advantages:

High strength: 12mm quartz fiber chopped strands for ablation have no micro-cracks on the surface, and the tensile strength is as high as 6000Mpa, which is 5 times that of high-silica fiber and 76.47% higher than E-glass fiber.

Good insulation performance: 12mm ablation quartz fiber chopped wire has a resistivity of 1*1018Ω·cm-1*106Ω·cm at 20-1000 degrees, which is a good electrical insulation material.

12mm quartz fiber chopped strands for ablation have stable chemical properties and can adapt to working environments such as acid and alkali resistance for a long time, as well as harsh working conditions such as high temperature, cold, and stretching.

4. Product application:

Ablative-resistant materials (thermal protection materials, exhaust pipes)

Thermal insulation (engine casing protective cover, fuselage fireproof partition, semiconductor, optical fiber manufacturing)

High-temperature catalyst carrier materials (automobile exhaust treatment, industrial air purifiers)

Glass manufacturing (tempering furnace high-temperature materials)

High temperature and hot acid gas liquid filtration

Dental posts and prosthetic bone reinforcement materials

Replace high silica fiber. Ceramic fiber, glass fiber.