Quartz Fiber: Revolutionizing Semiconductor Insulation

Quartz fiber, a marvel of modern engineering, stands as a testament to the incredible advancements in material science. This high-performance fiber has garnered significant attention for its unparalleled properties, particularly in the demanding field of semiconductor applications. As industries continue to push the boundaries of technology, the need for reliable and efficient insulation materials becomes paramount. Enter quartz fiber, a game-changer that promises to elevate the standards of thermal management in semiconductor devices.

Quartz Fiber's Versatility

In the realm of semiconductor manufacturing, where precision and performance are non-negotiable, Quartz Fiber emerges as a beacon of innovation. Its exceptional heat resistance and low coefficient of thermal expansion make it an ideal candidate for high-temperature insulation shields. These shields play a pivotal role in safeguarding sensitive electronic components from extreme temperatures, ensuring optimal operation and longevity of the devices.

Key Applications:

● Thermal Barrier in Semiconductor Processing: Quartz fiber’s ability to withstand temperatures up to 1000°C without compromising its structural integrity makes it perfect for use in furnaces and kilns involved in semiconductor fabrication.

● Insulation for Integrated Circuits (ICs): By incorporating quartz fiber insulation, manufacturers can significantly reduce heat transfer within IC packages, enhancing overall system efficiency and reducing the risk of overheating.

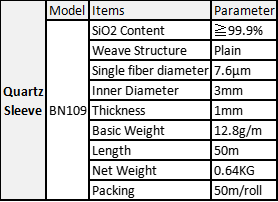

● Protective Sleeving for High-Temperature Wires: Electrical wiring within semiconductor equipment often operates under intense heat. Quartz fiber sleeves offer a lightweight yet robust solution, preventing thermal runaway and maintaining signal integrity.

Distinctive Features Setting Quartz Fiber Apart

Beyond its primary application as a high-temperature insulator, Quartz Fiber boasts a myriad of characteristics that further solidify its position at the forefront of advanced materials technology. Let's delve into some of these standout features:

● Unmatched Thermal Stability: Unlike conventional insulation materials that degrade under prolonged exposure to high temperatures, Quartz Fiber maintains its form and function, ensuring consistent performance even after repeated thermal cycling.

● Chemical Resistance: Resistant to most acids, alkalis, and organic solvents, this fiber is ideal for harsh chemical environments commonly found in semiconductor fabs, providing long-lasting protection against corrosion and degradation.

● Low Outgassing: A critical factor in vacuum environments, Quartz Fiber exhibits minimal outgassing, preserving the cleanliness and purity of semiconductor processes and reducing contamination risks.

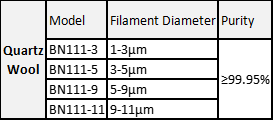

● High Purity: Manufactured to stringent specifications, our Quartz Fiber contains negligible impurities, eliminating the potential for unwanted doping or interference in sensitive semiconductor circuits.

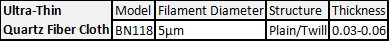

● Flexibility and Strength: Despite its ultrafine nature, Quartz Fiber combines flexibility with impressive tensile strength, allowing for easy handling and installation while maintaining durability under stress.

In conclusion, Quartz Fiber represents more than just an insulation material; it embodies a leap forward in enabling next-generation semiconductor technologies. Its unique blend of thermal stability, chemical resilience, and mechanical strength positions it as an indispensable component in the pursuit of smaller, faster, and more energy-efficient electronic devices. Embrace the future of semiconductor manufacturing with Quartz Fiber – where innovation meets reliability.